Our old farmhouse-y Stratford house, when we started our renovation project, had new-ish thin-strip glossy wood in the larger rectangular room, original 1920s’ worn floorboards in a variety of patches of wood in the south room (the kitchen, then) and imitation-wood laminate in the 2000 addition, which on the main floor houses the two-piece washroom and the “whatever” room we used as an office. There were transition bumps at each juncture, with a particularly large one between the hall and then-kitchen: The kind of bump where you warn guests to prevent inadvertent face-plants as someone found their way to the washroom.

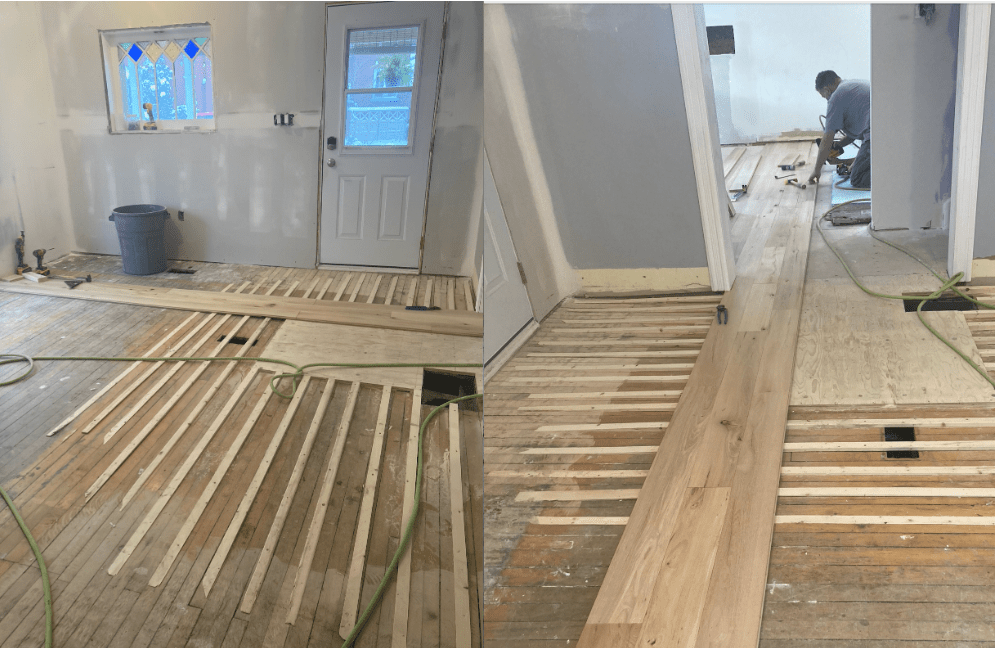

When we removed the new-ish thin-strip flooring, we found battered, old wide floor boards underneath. We took that as a sign that our choice of a single flooring to cover the whole first floor, except for tiled entrance halls, was the right one.

While we were in the early planning stages of this renovation, our contractor mentioned a place in nearby Waterloo, Ontario, that salvaged old wood. We were intrigued and made our way to the Timeless Material Company. They describe their process thus: “Operating over the past 20 years, The Timeless Material Company in co-operation with Kieswetter Demolition have carefully curated and meticulously reclaimed material from hundreds of historic buildings including century homes, factories, wineries, barns, and churches and diverted over a million board feet of material otherwise destined for the landfill.”

The place is worth a visit even if you aren’t on Renovation Road, particularly if you grew up in Waterloo County, as I did. This place, housed in a large converted barn structure, has harvested my childhood. Not only do they take old wood and re-mill it to make easier-to-install click-groove flooring; they also collect signage from local buildings whose lifespan has past. Ali Baba! (the fancy steakhouse restaurant of my youth). The Seagram Museum! The Breithaupt Leather Company! The company salvages other items too — from floor grates to clawfoot tubs — but we were there for the wood.

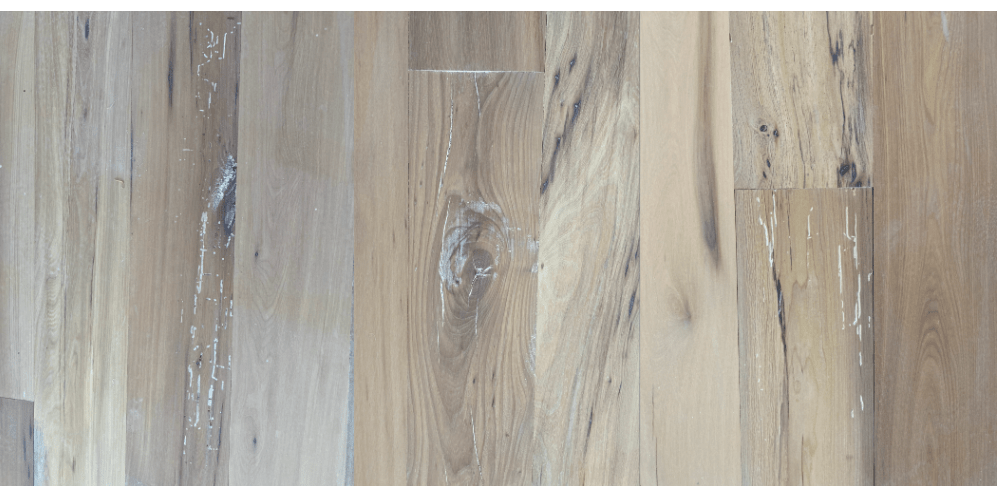

I wanted a light, pale flooring to set off our teak furniture: many woods and finishes turn an amber-gold colour and that’s too close to the warm wood of teak. Timeless Material had a re-milled mixed hardwood that fit the bill. It’s a “locally sourced hardwood material that is re-milled as flooring with tongue & grove profile for easy install. Contains a mix of species such as elm, ash, oak, maple, beech, and may contain some cherry and walnut.” The salesperson recommended Osmo Raw finish, designed to dry neutral without that amber tone. The sample provided looked great.

Sold.

The shipment arrived at the house and it was a thing of beauty. And yes, it looked great with the teak.

Our contractor, Jerry Walsh, and his team pulled a levelling miracle, using the green-laser guides and years of experience to shim and shuffle so that the entire main floor could flow as one even surface.

The installed floor was perfect. Just the way we wanted it. It needed the finish applied, and we were done.

My partner is a big fan of the British TV series, The Vicar of Dibley. There’s one character, Jim Trott, who, after eating something awful, pronounces it, “a di-zah-ster!”

After the first coat of finish was applied, we had “a di-zah-ster!” on our hands.

This Osmo Raw finish appeared milky when wet, although we figured it would dry clear.

It did not.

The finish got into every one of those character-filled nicks, knots, cracks and nail holes that are part of the charm of re-milled, reclaim old wood flooring. And it dried white — as if someone had spilled white paint on the raw wood and wiped it up, but couldn’t get the white out of any indentation.

It was my first, and let’s hope last, moment for tears, in this renovation.

We reached out to Timeless Material. The manager stood by the finish recommendation but said “I understand what you’re describing about it pooling in cracks.” He referred me to the manufacturer for help.

After providing detailed descriptions and photos, we again were told this was the right finish — but, without admitting it directly, it really isn’t the thing to use with reclaimed wood. Nick Eaton from Osmo wrote: “Because this floor was completed with reclaimed material, it would have benefited from an application of wood filler to fill gaps, cracks, and natural imperfections in the wood, prior to final sanding and finishing.” Gee. if we had wanted a perfectly smooth floor with no character quirks, we would have bought laminate.

Our contractor worked overtime to sand off the finish. My partner and I spent several hours over a Saturday and Sunday on our hands and knees, using tiny, sharp implements (I had a nail file and manicure scissors; he had a steel dental pick) to scrape out the accumulated white goo, as much as possible, from knots, nail holes and cracks in the wood. We couldn’t get it all, but when we were done, the floor looked almost as good as when it was first laid down.

We still needed to find a protective coating, however, that wouldn’t turn the floorboards amber.

Jerry had a finish he had used on many floors that we tried in a corner where the kitchen cabinets will cover the floor boards but it dried too dark on this light wood. Our painter, Jessica Elliott, had a finish she thought would work. More sample coats. Finally, we had a winner.

After three coats, the floor is now protected, and looks like this:

So, word to the wise: Raw Polyx finish and reclaimed wood do not play well together. Even with that moment of “di-zah-ster”, I’m glad we’ll be treading on wood that came from some other farmhouse in my home Waterloo County for — let’s hope — many years ahead.

I so enjoy your stories. Glad you got over your your disaster! Everything looks beautiful.

LikeLiked by 1 person