Our little farmhouse-style home had five different flooring surfaces over the first floor. One of the things, beyond moving where the kitchen was located, that turned this renovation into a whole first-floor do-over was our desire to have fewer flooring materials used — ideally, two — to make the space flow better. We chose to put wood throughout all the rooms and went on the hunt for a tile to use in both the front and back halls, where you need a water-impervious surface to handle wet umbrellas and snowy boots.

My dear lord, but there is a lot of tile out there.

I didn’t want anything too grand or looking like it was inspired by an Italian villa. At first, I thought perhaps we should just pick a couple tile colours and alternate them in a checkerboard or diamond pattern: something simple to complement the home’s simple vibe.

The designer we consulted had a favourite tile supplier in Toronto, Mettro Source, and suggested we should go there to look at all the choices in person. Tile is one thing that’s really hard to get a true feel for, looking at online pictures.

There are hundreds of tile stores in the Greater Toronto Area, many of which are in the same Yorkdale neighbourhood where Mettro is located. It was a relief to think, let’s just find something we like at this one store, and be done with it.

We had a viewing appointment (COVID restriction times, still) and had the run of the showroom. We narrowed down to several choices and took away a box of samples. Ultimately, we were most drawn to a quirky tile in a pattern called Tiebele.

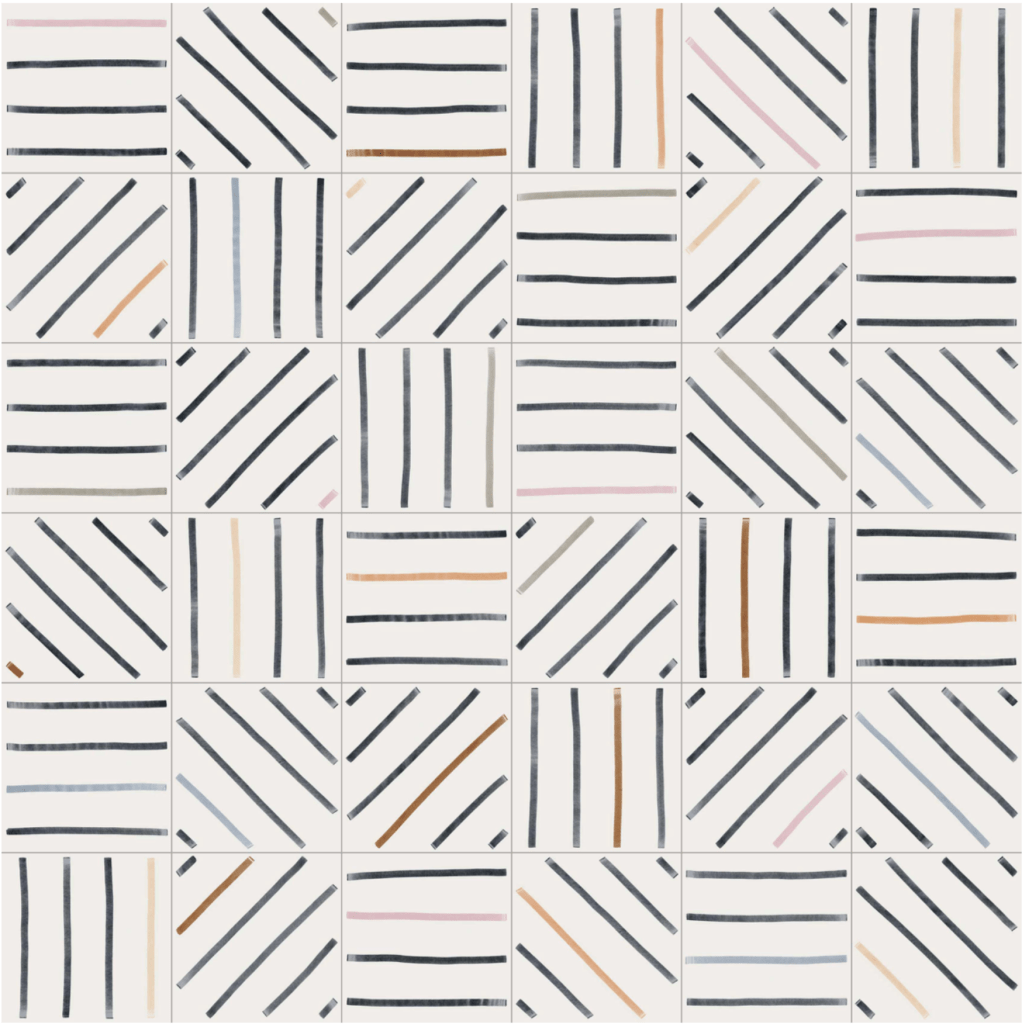

These 8″x8″ tiles come in several variations, but all feature what look like hand-drawn shapes or lines, as if done with a chisel-tip magic marker. At first I was enamoured of the tile that had four leaf-like ovals on each, but thought it might get too busy. We chose to order the version pictured above, which has a wide variety of different tiles, some with diagonal lines and some with lines up-and-down (or side to side, depending on how you turn the tile).

Mettro Source suggested we order our tiles well in advance as they were imported from Spain. So that we did, with the promise the store would hold the tiles for us in Toronto until we needed them shipped to Stratford.

I discovered that these tiles were made by Vives, a company based in L’Alcora, Spain, a town of 10,000 inland from the country’s west coast. It’s about an hour north of Valencia and three hours south of Barcelona, where a decade ago I spent a wonderful week on a food and wine tour, learning how to make Spanish dishes from paella to pan con tomate. While where possible we were sourcing renovation supplies from Canadian companies, we made an exception for these tiles, and I was glad to learn I kinda sorta had been near where they are created.

Months passed between tile order and the time when my contractor suggested it would be good to get the tile shipped to us within the next couple weeks. As well, we had decided to tile a smaller area in the back hall than originally planned, so I now only wanted 90 square feet of tile, plus a bit extra for waste and cutting, rather than the 112 square feet we had ordered (and already paid for).

I emailed.

No reply.

I phoned.

No-one picked up.

Left a message.

Phoned again.

This time, one of the co-owners answered and said the other co-owner would call me back to speak to me about the order.

It turns out, they were scrambling because a chunk of our order lay in shattered ruins.

We apparently were not the only people in Ontario who wanted this tile: the store ordered a skid for delivery from Spain. When it arrived, boxes of tiles from this skid were sent out to the other orders and ours were the only ones remaining, held until we let them know to ship. The remaining boxes seemed undamaged.

They weren’t.

The owner went through all the remaining tile and pulled together 87 square feet intact. He suggested adding one of the other patterns from the series to mix in with the rest, or choose another pattern for the smaller back hall. I really didn’t want to do either as the whole point of getting new tile was to harmonize front and back. So he shipped what was there. I figured we’d get the front hall done and then have to order a new batch for the back hall: dye lots can change in these kind of crafted tiles and it wasn’t advised to mix dye lots in the same floor area.

Christine, our tiler, said the pattern made her “nervous and excited”. She sorted all the tiles into like-with-like piles, then started the fun but challenging puzzle of laying them out. She came up with a great seeming-random but also nicely patterned design.

The tiles fit in the front hall perfectly, without cutting, six abreast, with one small height trim to the final tile row by the front door. Every tile was exactly 8″ x 8″. That exactitude saved the day.

“There might be enough to do the back,” Christine said.

More puzzle piecing and, by the grace of Saint Barbara, the patron saint of tilers, there were enough tiles for the back hall area too with six tiles left over, including the sample I got on our showroom visit.

If we hadn’t decided to reduce the footprint for tiling in the back hall — a suggestion from Hilton, our contractor’s No. 2 for demolition and construction — there’s no way the 87 square feet remaining from the damaged shipment would have covered the space. In future, whenever I notice these tiles, I’ll remember the nail-biter moments and the skippety-hop of happiness when we finally knew it would work out, in the end.